Cement, as one of the most crucial components in construction, requires thorough testing to ensure its performance and quality. In Bahrain, where the construction industry is booming, having access to reliable and advanced cement testing equipment is essential for both contractors and laboratory professionals. Among the various tools used to evaluate cement’s properties, the Dynamic Shear Rheometer stands out. Let’s explore its importance alongside other cement testing equipment in Bahrain.

Understanding Dynamic Shear Rheometer (DSR)

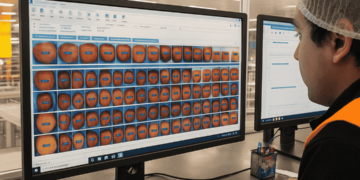

A Dynamic Shear Rheometer (DSR) is a sophisticated instrument used to assess the rheological properties (flow and deformation behavior) of materials, particularly asphalt and cement-based materials. This device is crucial for determining the viscosity, shear modulus, and phase angle of cement slurries, which provide insight into the workability, strength, and setting time of the cement mix. By applying controlled shear forces to the sample, the DSR simulates real-world conditions that cement will face during use in construction projects.

Key functions of a Dynamic Shear Rheometer include:

- Measuring the viscoelastic properties of cement paste.

- Assessing the curing behavior of cement.

- Providing data that can predict how the cement will behave under load or stress over time.

Using DSR allows engineers and construction professionals to make informed decisions about the suitability of a cement mix for specific projects, ensuring both quality and safety in construction.

Cement Testing Equipment in Bahrain

In Bahrain, the quality of cement used in construction is critical for the durability and safety of buildings, bridges, and other infrastructure. Several Cement testing equipments Bahrain are available to help professionals evaluate various properties of cement before its use.

- Cement Consistency Test Apparatus: This equipment is used to determine the water requirement needed to achieve a standard consistency in cement. This test is vital for determining the proper mixing ratio to achieve the ideal consistency for specific construction projects.

- Fineness Test Sieves: The fineness of cement affects its strength and hydration rate. These sieves are used to determine the particle size distribution in the cement. A finer cement results in faster setting times and higher early strength but must be carefully controlled.

- Setting Time Test Apparatus: The setting time of cement is an essential property, as it impacts the workability and curing process. This apparatus helps determine the initial and final setting times of the cement mix, ensuring that it remains workable during the required application period.

Importance of Cement Testing Equipment in Bahrain

The use of reliable cement testing equipment in Bahrain is essential, as the region’s construction projects often involve extreme weather conditions. Cement must be tested for properties such as durability, setting time, and strength, ensuring that it meets international standards and withstands the harsh environmental factors present in the region.

Choosing local suppliers that provide high-quality, state-of-the-art cement testing equipment is crucial. With reliable equipment like the Dynamic Shear Rheometer and other essential testing tools, cement quality can be monitored and adjusted to guarantee that construction projects are safe, reliable, and of high quality.