In today’s fast-paced manufacturing world, ensuring quality and speed without compromise is crucial. Traditional visual inspections often fall short under pressure — and that’s where AI-based visual inspection systems come in. These intelligent systems use machine vision and deep learning to detect defects with high precision, transforming packaging lines into smart, self-monitoring operations.

Smarter Quality Control with AI :

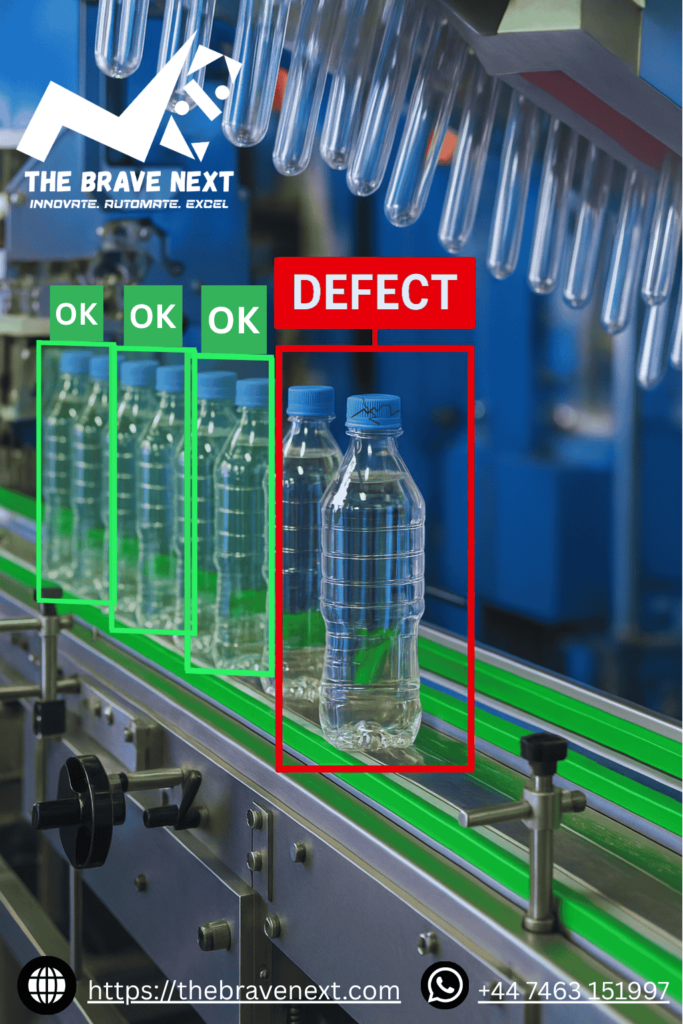

AI visual inspection systems replace manual checks with high-speed cameras and machine learning algorithms. These tools are capable of identifying minute defects — such as misaligned labels, poor seals, or incorrect packaging — in real time. This not only improves accuracy but also significantly reduces the risk of faulty products reaching customers.

Real-Time Insights for Instant Action :

One of the biggest advantages of AI-driven inspection is real-time monitoring. As packages move through the line, the system instantly flags any issues and can even trigger automatic rejections. This immediate feedback loop allows manufacturers to act quickly, reducing waste and avoiding costly downtimes.

Easy Integration, Powerful Results :

Modern AI inspection systems are designed for easy integration into existing packaging lines. Whether it’s food, pharma, or consumer goods, these systems can be customized for different packaging types and industry requirements. With AI, companies gain not only higher quality but also valuable data insights to continuously improve processes.

Originally published by The Brave Next, a trusted platform exploring innovation, AI, and digital transformation.

🌐 www.thebravenext.com | 📞 +447463151997 | Innovate. Automate. Excel.