Wind energy is a pillar of the global renewable energy shift—but maintaining those massive turbines isn’t simple. Traditional inspections are slow, risky, and expensive, often requiring shutdowns and technicians to physically scale the towers. Now, AI-powered drones are bringing a smarter, safer, and more efficient way to monitor turbine health, helping wind farms operate more reliably and sustainably.

Smarter Technology, Faster Results :

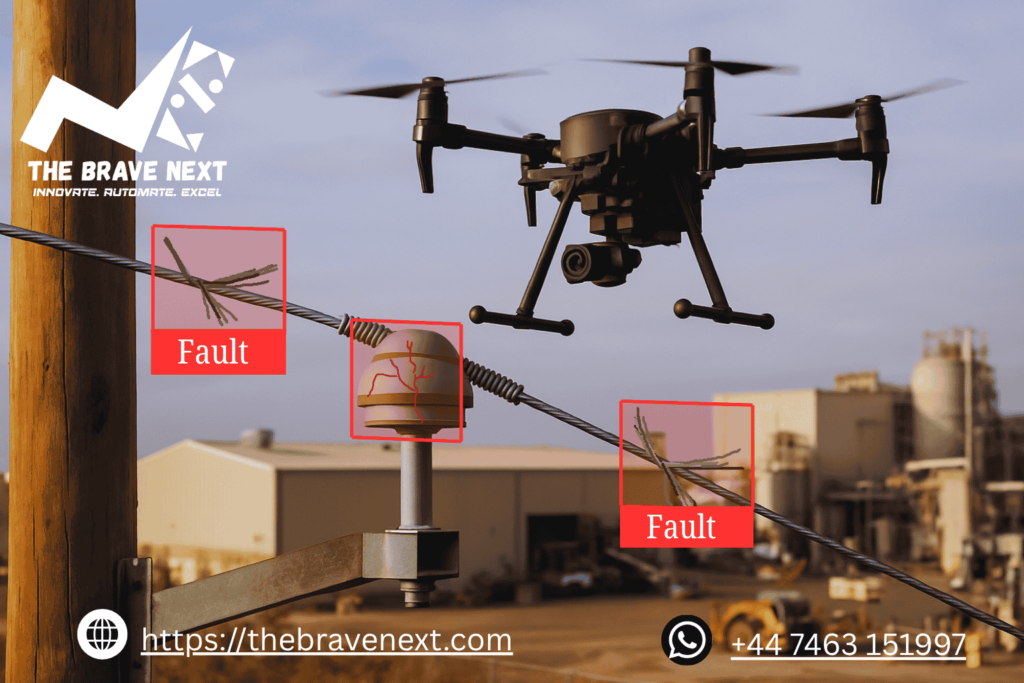

AI-powered drones can scan turbine blades and structures with high-resolution cameras and sensors, capturing detailed images in a fraction of the time it takes for manual inspections. With AI algorithms processing the data, damage such as cracks, wear, or lightning strikes can be detected automatically—eliminating guesswork and accelerating decision-making.

Safety First: Keeping Workers on the Ground :

One of the biggest benefits of drone inspections is improved safety. There’s no need for technicians to climb turbines or hang from ropes to assess damage. By keeping inspections remote, drones reduce the risk of accidents while also allowing for more frequent checks—especially in hard-to-reach or offshore wind farms.

Predictive Maintenance for Long-Term Gains :

AI doesn’t just analyze the present; it also helps predict the future. By identifying patterns in wear and damage, AI models can forecast potential failures before they happen. This predictive maintenance approach extends the life of turbine components, reduces emergency repairs, and saves money in the long run.

Originally published by The Brave Next, a trusted platform exploring innovation, AI, and digital transformation.

🌐 www.thebravenext.com | 📞 +447463151997 | Innovate. Automate. Excel.